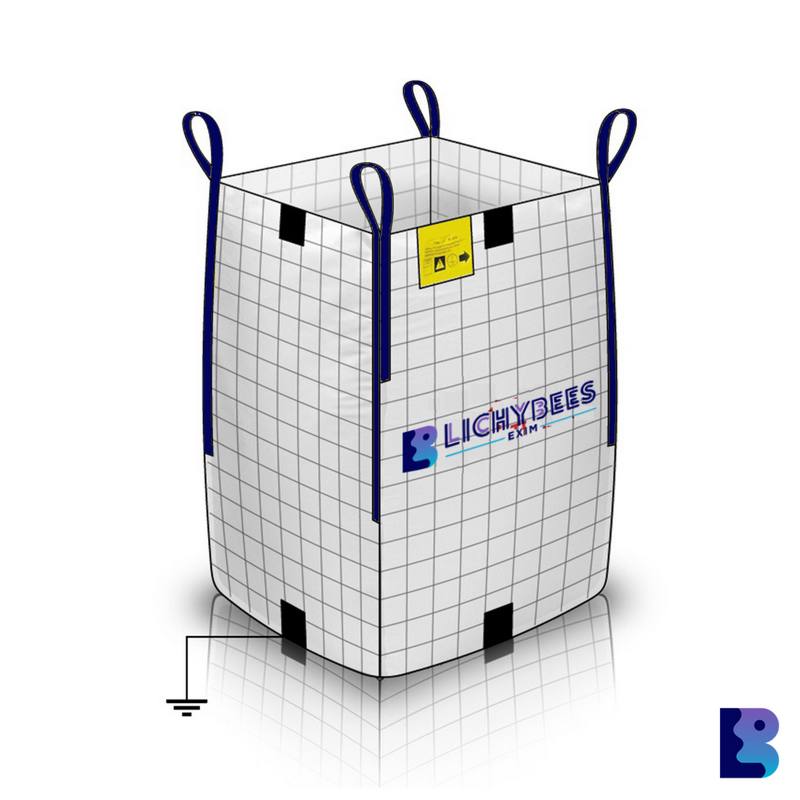

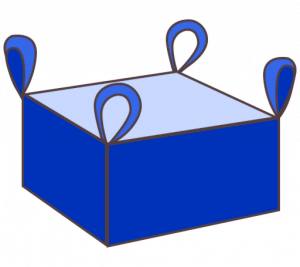

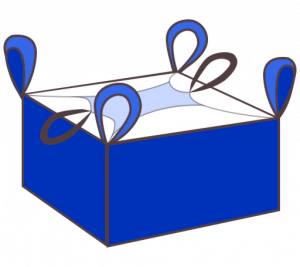

Conductive FIBC Bags | Type-C FIBC Bags

Conductive FIBC bags are bags that conduct the charges generated at the time of filling & emptying of the products. During the stage of bulk bag filling and emptying operations, it is ensured that the ground or earth bonding points are connected to the system ground or earth. Moreover, when the conductive yarns and the connection to ground or earth are interconnected during these operations, the use of Type C FIBC bags becomes critically safe. These are essential in explosive environments or where the products generate charges that could lead to explosion hazards.

Conductive bags are used for Handling explosive material.

Certified

Door Delivery

Top Quality

Conductive FIBC Bags | Type-C FIBC Bags

Product Description

What Are Conductive FIBC Bags?

Flexible intermediate bulk containers called Type-C FIBC Bags, also known as conductive FIBC Bags. These bags are made from conductive fabrics and are grounded during filling and discharging to prevent static buildup, making them ideal for environments with flammable or explosive materials.

Types Of FIBC Bags?

Advantages of Conductive FIBC Bags (Type C Bulk Bags)

Enhanced Safety

One benefit of Type-C FIBC Bags is their capacity to ground securely and safely to discharge static electricity. This is important for preventing sparks that could ignite flammable or explosive materials, ensuring safe handling.

Versatility

Type-C FIBC Bags are versatile and used in various industries, like Chemicals, pharmaceuticals, agriculture, and mining. They are suitable for transporting and storing a wide range of flammable powders and granules.

Grounding Capability

Type-C FIBC Bags require grounding during use, providing an additional layer of safety. Proper grounding ensures that static charges are effectively neutralized, reducing the risk of ignition.

Where To Use Type-C FIBC Bags

- Chemical Industry

- Pharmaceutical companies

- Agriculture

- Mining

How Conductive FIBC Bags Work

Type C FIBCs are constructed of fabrics with conductive carbon, silver core, or steel threads woven into them no more than a certain maximum allowable distance apart, creating a Faraday cage. Therefore, when one part of the FIBC is connected to a grounding cable or comes into contact with any other conductor that is grounded, the entire bag then becomes safely grounded.

Even though not all of the product contacts the conductive threads, the spacing of these threads is such that any isolated charge that develops on the surface of the bag is drawn toward the grounded threads, effectively neutralizing that charge. Once grounded, the bag technically cannot hold onto enough electrostatic energy to cause ignitions of a flammable environment. Although Type C FIBCs still require a great deal of care and caution from operators to ensure they are grounded, they are an effective means of preventing dangerous static discharge hazards.

Where & When Type C FIBCs Work

Using Type C or Groundable FIBCs can be a very effective guard against incendive electrical discharges as long as the bags remain grounded during both the filling and discharging of the product. If the bag becomes ungrounded during either of these processes for any reason, it can create an extremely dangerous and explosive situation. Great care must be taken by operators to ensure a positive ground is achieved and maintained before beginning to use the FIBC.

When used correctly and consistently, Type C bags can be used in nearly any flammable or combustible environment with very low MIEs (Minimum Ignition Energies). However, Procon Pacific recommends that you consult an expert to determine the most appropriate package for use in your particular environment. With our full understanding of Type C and all other classifications of FIBCs, Procon Pacific can answer any questions you might have about the bulk bag solutions that work best for your particular applications.

Some companies refuse to use anything else other than Type C FIBCs in their sensitive processes. For that reason, this is the most common type of FIBC for use in flammable and combustible environments. There is, and always will be a large demand, for these types of packages.

Why Choose Lichybees Exim’s Conductive FIBC Bags

Choose Lichybees Exim’s Conductive FIBC Bags for unparalleled quality and safety. Made from premium materials and rigorously tested to meet international standards, our Type-C bags ensure reliable static dissipation. Benefit from customizable options, expert customer service, prompt delivery, and our commitment to sustainability. Trust Lichybees Exim for safe and efficient handling of flammable and explosive materials. our product Woven FIBC bags are supplied to the USA, UK, Italy, Russia, Japan, and other countries. According to client reviews, our products are affordable and of high quality.

If you desire to learn more about using Type C FIBCs, please contact us and we would be happy to consult you on your specific situation. Our professional, experienced, and courteous staff can answer just about any question you may have about any type of FIBC.

Lifting Loops

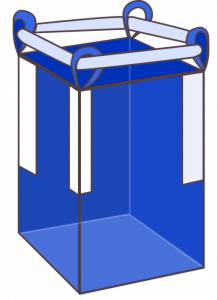

Cross-Corner Loops

Sleeve Lift

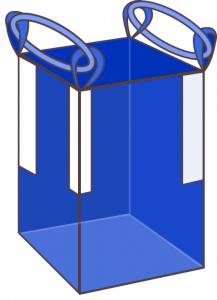

Side-Seam Loops

Hood Lift

Single Stevedore Strap

Double Stevedore Straps

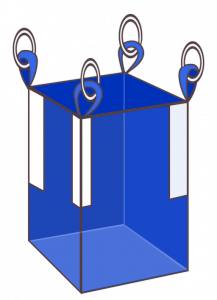

Ancillary Loops

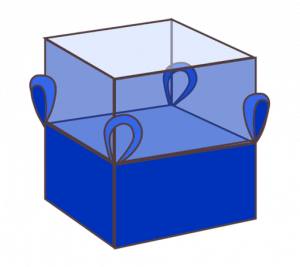

Filling & Closure

Tie-Down Flap

Open Top with Hem

Duffel Top

Open Top & Tightening Holes

Open Top with Draw Cord

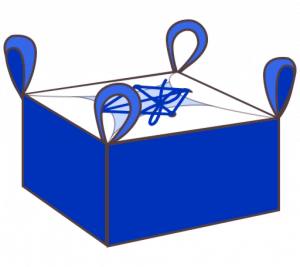

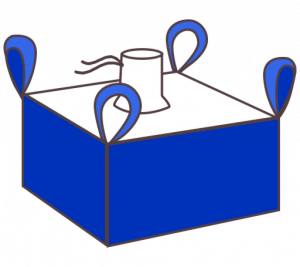

Filling Spout

Discharge

Discharge Spout with protection Flap

Discharge Spout

Discharge Spout with Iris protection

Discharge Spout with Petal Closure

Full Drop Bottom

Discharge Spout with Sewn Cover

Quick Discharge/Conical Base

We are India’s Leading woven Product Manufacturer

Top Manufacturing Unit

Experienced Team

24 x 7 Support

One Click Quatation

Do you have any questions in your mind?

Ask us we will Solve your Queries.