PP Laminated Non Woven Fabric

PP (Polypropylene) laminated non-woven fabrics are a type of composite material made by laminating a layer of polypropylene film to a layer of non-woven fabric.

PP laminated non-woven fabrics are used in a wide range of applications, including packaging, agriculture, construction, and the production of bags, tablecloths, outdoor furniture covers, medical gowns, bags, and protective clothing due to their durability, water resistance, and breathability.

Certified

Door Delivery

Top Quality

PP Laminated Non Woven Fabric

What is PP Laminated Non Woven Fabric?

Polypropylene or PP is a multipurpose plastic polymer that is renowned for its resilience to chemicals and strength. PP improves the performance and durability of non woven fabrics when it is laminated and produces a high-performance material that may be used in a variety of applications. PP/PE laminated non woven fabric which is bonded and laminated fabrics is produced by using melt PE raw material spreading uniformly on the surface of pp spunbond fabric. After cooling and pressing one type of composite non woven fabric is ready.

PP Laminated Non Woven Fabrics Specifications

Product features of Laminated Non woven fabric

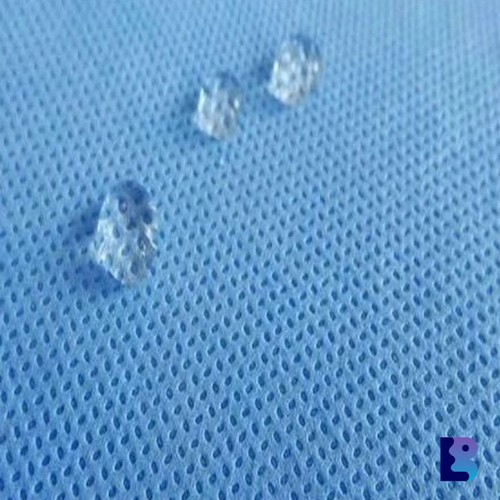

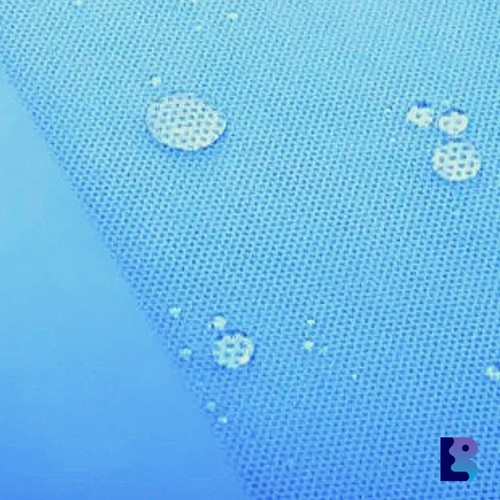

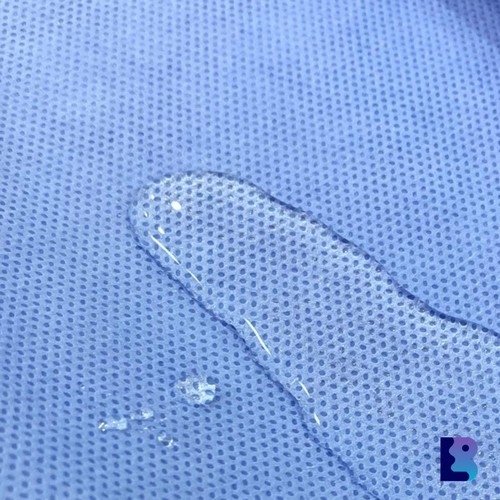

- Resistance to moisture & ultra violet rays

- Durability

- Breathability

- Lightweight

- Good strength

- Liquid repellent

- Optimum quality

- Eco-friendly

- Soft and evenness

- Cost-effective

- Water Resistant

PP laminated non woven fabric has various uses, including

- Shopping bags

- Medical gowns and drapes

- Protective clothing

- Packaging materials

- Furniture upholstery

- Agricultural covers

- Barrier material in food packaging

- Geotextiles for landscaping and erosion control

- Insulation material

- Carpet underlay

- Wall covering material

Where to use Laminated Non woven fabric?

- Packing & Shopping bag

- Daily used Products

- Non Woven Garment Fabrics

Types of Laminated Non woven Fabric

- PP Laminated Non Woven Fabric

- Metallic Laminated Non Woven Fabric

- Hydrophilic Non woven fabric with Lamination

Advantages of PP Lamination

Enhanced Strength

PP lamination dramatically raises non woven textiles strength, enabling them to be used in more demanding applications.

Improved Barrier Properties

Lamination improves a fabric’s resistance to liquids, including water, oils, and other substances, which is important for protective apparel and packaging.

Environmental Resistance

These textiles have a long useful life because of their outstanding resistance to environmental elements including UV rays and extremely high temperatures.This PE/PP laminated non woven fabric is mostly used for medical and hygiene cloth such as surgical gown, isolation gown, disposable protective clothing, etc.

Manufacturing Process of PP Laminated Non Woven Fabric

We describe some steps of production of Pp laminated non woven fabric in india. Each step ensures the final product meets the desired specifications.

Production of non woven fabric

The non woven fabric is created by many processes and techniques, including spunbond, meltblown and needle punch. select the appropriate fabric, such as polypropylene fabric, for the non-woven fabric manufacturing process.

PP Film Production

The PP film is produced by extruding polypropylene resin to get the desired thickness and properties. This PP film acts as the laminating layer that will be bonded to the non woven fabric.

Lamination Process

The PP film and the non woven fabric are bonded together during the lamination process. This can be done using heat, pressure, or adhesive, depending on the specific requirements. The lamination enhances the strength, durability, and barrier properties of the fabric. Laminated non woven bags are strong, recyclable and reusable so it is popular everywhere worldwide.

Quality Control and Finishing

At last, the laminated fabric undergoes rigorous quality control checks to ensure it meets industry standards. The finished product is then cut, rolled, or packaged according to customer requirements.

After passing through all processes Non woven fabric is ready for industries use. In Lichybees Exim Pp laminated non woven fabric price is cheaper than any other. We are a manufacturer and supplier of woven and non woven fabrics, covers and bags in the USA, UK, Canada, Brazil, New Zealand, Spain, Italy, Singapore, Mexico, at your doorstep.

Conclusion

PP laminated non woven fabric, which offers a special blend of strength, durability, and environmental resistance, represents a substantial improvement in the textile sector. Its many uses in the packaging, building, medicinal, and agricultural industries demonstrate its exceptional performance and adaptability.

Lichybees Exim is professional laminated non woven fabric manufacturer. We supply high quality non woven fabric at lower prices worldwide. Our goal is to keep the environment clean and plastic free.

We are India’s Leading Non woven Product Manufacturer

Top Manufacturing Unit

Experienced Team

24 x 7 Support

One Click Quatation

Do you have any questions in your mind?

Ask us we will Solve your Queries.